We are Authorized Dealers, Manufacturer, Supplier, Distributor, Trader, Exporter, Importer, Maintenance, AMC Services Provider of Micro Vickers Hardness Testers, Digital Vickers Hardness Testers, Digital Micro Vickers Hardness Testers, Digital Micro Vickers Hardness Tester with Auto Turret and our setup is situated at Pune, Maharashtra, India.

Leading Distributor / Channel Partner of micro vickers hardness tester, digital vickers hardness tester, digital micro vickers hardness tester and digital micro vickers hardness tester with auto turret from Pune.

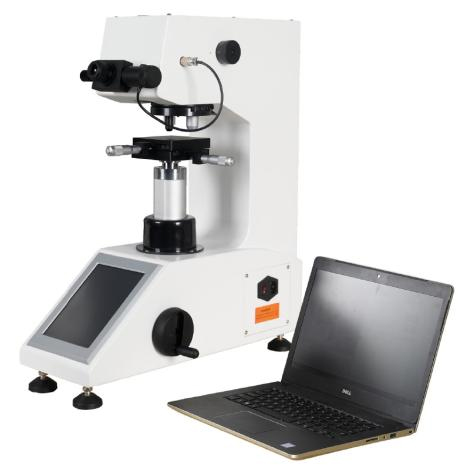

Salient Features of our Top End Model :

• Auto Turret

• Optical Measurement with Digital Encoder

• Worm UP/DOWN Movement

• Same Image at the same time is shown on Monitor and Optical System

• Touch Screen

• Direct ECD value

• 15 years Spare Back up

• Digital Computerized

Highly precise hardness tester suitable for test of widely hardness ranges from softest to hardest materials. This machines available with Manual & automatic turret system guided by optical cross rail to achieve highly accurate & precise results. This machine is equipped with built-in encoder with click button on encoder to avoid human errors. Equipment is also featured with a DATA storage & calibration. Most compact in size (540*260*650mm) & light weight (50kg).

Features:

• Automatic Turret System.

• Multifunctional 8 inch LCD touch screen panel.

• Flexible & Foldable design of hand wheel.

• 10X digital Encoder with built in encoder.

• 8P Data Storage system with store up to 300 Test reports.

• LED cold light source (can use continuously for 24 hrs.)

• Easy conversion of hardness scales.

• Can print results data Min & Max values with graph facility

| Model | MMT-X8 |

| Turret Movement | Automatic |

| Measuring Eyepiece | 10X & 40X |

| Min. Measuring unit | 0.01µm |

| Testing Force | 10g (0.098N), 25g (0.0245N), 50g (0.49N), 100g (0.98N), 200g (1.96N), 300g (2.94N), 500g (4.9N), 1000g (9.8N) |

| Hardness Scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 |

| Hardness conversion scale | HRA, HRB, HRC, HRD, HRF, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HV, HK, HBW. |

| Hardness Range | 1HV – 4000HV |

| Hardness Value of reading | 8 inch LCD touch screen display |

| Magnification | 100X for observation & 400X for Measurement |

| Dwell time | 1 - 99 sec |

| Loading Control | Automatically (Load / Dwell / Unload) |

| X-Y Testing table | 100*100 mm, Travel up to 25*25 mm with resolution 0.01mm |

| Max. Height of Specimen | 100 mm (Vertical) |

| Max. depth of specimen | 130 mm (Horizontal) |

| Light source | Cold light source 5V/3W LED (Can be continuous use for 24Hrs, No heat generate, ensure stable working, Services life can reach 1,00,000 hrs.) |

| Executed Standard | IS1501-2 , ASTM384 & ASTM E92 |

| Overall dimension | 540*260*650mm (L x W x H) |

| Net weight approx. | 65 kg |

| Power supply | 220V + 5%, 50/60 Hz (110V is available) |

| Standard Accessories | 10x Omron digital micro eyepiece | 1 No |

| 10X & 40X objective lens | 1 No. Each | |

| Vickers Indentor | 1 No. | |

| X-Y Testing Table | 1 No. | |

| Hardness Test Blocks (HV1 & HV0.2) | 1 No. Each | |

| 1 No. Each | 1 No. | |

| Level Bubble | 1 No | |

| Allen Keys | 1 Set | |

| Leveling Screw | 4 Nos. | |

| Power Cable | 1 No. | |

| Manual Book | 1 No. | |

| Dust Proof Cover | 1 No. | |

| Accessories Case | 1 No. | |

| Optional Accessories | Digital X-Y Table, Data transfer software, Built-in-printer (Hardness value- Max. & Min. value, Testing times & Avg. Value) | |

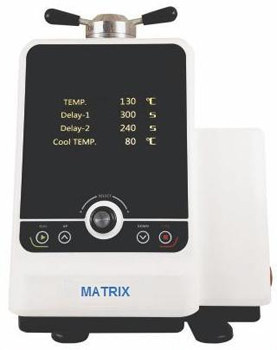

Touch Screen Automatic Mounting Machine

| Model | AM-30 |

| Mould Diameter | 30 mm |

| Heating temperature range | 100-200° C |

| Holding Time Range | 0-999 sec |

| Cooling Method | Water Cooling |

| Pressure | Automatically |

| Mould Preparation Capacity | Single Mould |

| Electric Power | 650W, 220V, 50Hz |

| Dimensional Weight | 350 X 450 X 470 mm, 48kg |

Touch Screen Manual Mounting Machine

| Model | MM-30 | MM-45 |

| Mould Diameter | 30 mm | 45 mm |

| Temperature Adjusting Range | 90-200° C | |

| Cooling Method | Air Cooling Fan | |

| Pressure | Manually by hand wheel | |

| Mould Preparation Capacity | Single Mould | |

| Electric Power | 650W, 220V, 50Hz | |

| Dimension / Net Weight | 440 X 253 X 310 mm, 32kg |

Double Disc Polishing Machine

| Model | MPM-2D |

| Disc Diameter | 203 mm |

| Grinding/Polishing Speed | 50-1000 RPM |

| Power | 550W, 220 Volt |

| Head Rotating Speed | 50 RPM |

| Sample Force | 0-40 N |

| Sample Capacity | 1-3 Nos. |

| Dimension/Net Weight | 700 X 600 X 278 mm, 45kg |

Double Disc Polishing Machine (Advanced)

| Model | MPM-2D(V) |

| Disc Diameter | Disc Diameter |

| Disc Diameter (Optional) | 10 Inch, 12 Inch |

| Grinding/Polishing Speed | 50-1000 RPM |

| Sample Force | 0.5 HP High Torque Motor |

| Power | 550W, 220 Volts |

| Dimension/Net Weight | 800 X 600 X 278 mm, 47kg |

MATRIX metallographic sample cutting machine is widely used to cut the various types of metal materials. These machines are equipped with cooling system which clear up the heat produced during sample cutting and avoid deformation of metal structure because of heating influence.

Automatic Cutting Machine

| Model | ACM-100X |

| Display | LCD Display with high resolution backlight |

| Cutting Capacity | 100mm |

| Cutting Method | Manual & Automatic |

| Way of infeed | Arbitrary adjustment |

| Infeed distance | Arbitrary Set, Adjustment and fixture position |

| Reset Mode | Automatic |

| Cooling System | Water Cooling with 3 ways |

| Effective workpiece Length | 200 mm |

| Spindle Speed | 2800 RPM |

| Coolent Tank Capacity | 65 liters |

| Cutting wheel dimension | 350mm X 2mm X 32mm |

| Motor | 4 HP (3 kw), 380V, 50Hz |

| Dimension / Net Weight | 1650 X 680 X 740 mm, 150kg |

Abrasive Cutting Machine

| Model | ACM - 60 | ACM - 80 |

| Front Cover | Fully Enclosed | |

| Cutting Capacity | 60 mm | 80 mm |

| Cutting Method | Manual | |

| Cooling System | Water Cooling | |

| Spindle Speed | 2800 RPM | |

| Coolent Tank Capacity | 50 liters | |

| Cutting wheel dimension | 250mm X 2mm X 32mm | |

| Motor | 2.9 HP (2.2 kw), 380V, 50Hz | |

| Dimension / Net Weight | 700 X 650 X 560 mm, 117kg | |

Manual Control Cutting Machines

| Model | MCM - 35 | MCM - 50 |

| Cutting Capacity | 35 mm | 50 mm |

| Cutting Method | Manual | |

| Cooling System | Water Cooling | |

| Spindle Speed | 2800 RPM | |

| Coolent Tank Capacity | 50 liters | |

| Cutting wheel dimension | 250mm X 2mm X 32mm | |

| Motor | 1.4 HP (1.1 kw), 380V, 50Hz | 2.9 HP (2.2 kw), 380V, 50Hz |

| Cutting Capacity | 30 mm | 55 mm |

| Net Weight | 60 kg | 80 kg |